What are Programmable Power Supplies?

Programmable power supplies are electrical devices that provide a controllable DC or AC output voltage and current, which can be precisely set, adjusted, and automated via digital interfaces such as USB, LAN, GPIB, or RS-232. Unlike traditional power supplies, which only allow manual adjustment, programmable power supplies let engineers program voltage, current, and waveform profiles for automated testing, simulation, and research applications.

Precise control: Voltage, current, and sometimes power can be adjusted with high resolution.

Dynamic output: Ability to sweep or step voltage/current over time or follow a defined profile.

Protection features: Built-in overvoltage, overcurrent, and thermal protections.

Communication interfaces: Allow integration into automated test setups (ATE) or lab systems.

Multiple operating modes: Constant voltage (CV), constant current (CC), and sometimes constant power (CP) modes.

Applications: Programmable power supplies are widely used in R&D, manufacturing testing, battery simulation, EV charger testing, electronic load emulation, and automated test systems. They enable engineers to simulate real-world operating conditions safely, reproducibly, and efficiently.

Industries Where Programmable Power Supplies are Applied for Research and Development

Programmable power supplies are widely used across multiple industries for research and development (R&D) due to their precise voltage and current control, programmability, and reliability. Key industries include:

Automotive & Electric Vehicles (EVs): Used for testing batteries, inverters, DC/DC converters, and charging systems under realistic operating conditions. Engineers can simulate battery charging/discharging cycles and validate EV components for efficiency and safety.

Renewable Energy & Energy Storage: Essential for testing solar inverters, wind turbine controllers, and energy storage systems. PPS allows simulation of fluctuating grid conditions, dynamic load profiles, and energy source variations.

Aerospace & Defense: Used for avionics, radar, and communication system development. PPS ensures accurate power delivery, supports complex testing sequences, and validates compliance with strict industry standards.

Semiconductor & Electronics Manufacturing: Applied for testing ICs, PCBs, and power electronics modules. PPS enables automated stress testing, functional verification, and validation of electronic components under controlled power conditions.

Medical Devices & Laboratory Equipment: Used to test precision devices such as imaging systems, diagnostic equipment, and lab instruments where stable and programmable power supply is critical for accurate R&D measurements.

Industrial Automation & Robotics: Supports development of motor drives, control systems, and industrial power modules by simulating variable loads, voltage sags, and transient conditions for reliability testing.

Top 5 Renowned Manufacturers of Programmable Power Supplies

Companies that manufacture programmable power supplies are typically specialized power electronics and test equipment providers that focus on precision, reliability, and flexibility for research, development, and production testing. These companies combine high-accuracy hardware, such as DC/AC sources, switching converters, and multi-channel outputs—with advanced software control to enable precise, repeatable voltage and current programming.

They are characterized by a strong emphasis on safety, protection features, and compliance with international standards (e.g., IEC, UL, or ISO). Their products often support automated testing, sequence programming, and integration with ATE systems, allowing engineers to simulate real-world operating conditions, perform stress tests, and validate the performance of electronic components, batteries, renewable energy systems, and industrial devices.

Modularity, scalability, and programmability are core traits, enabling their instruments to cover a wide range of power ratings—from low-power bench-top supplies to high-power multi-kilowatt systems—while maintaining precise control, stability, and energy efficiency.

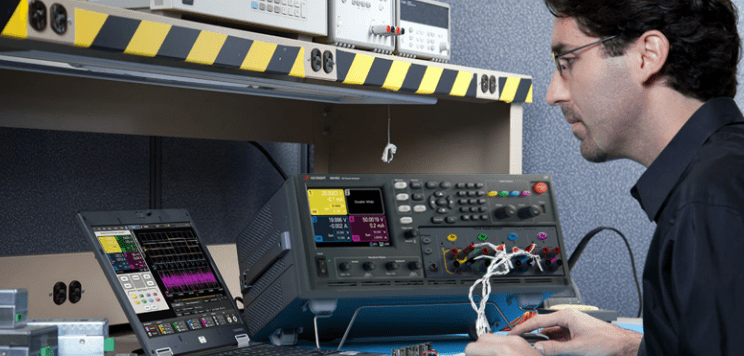

Keysight Technologies

Keysight Technologies is a global leader in electronic design and test solutions, with decades of experience providing high-precision instruments for R&D, manufacturing, and compliance testing. Their programmable power supplies are widely used in telecommunications, aerospace, automotive, and electronics industries, where high accuracy and stability are critical. Keysight emphasizes both bench-top usability and integration into automated test systems (ATE).

Product Range and Features:

E36200 Series: Compact bench-top programmable DC power supplies with single or triple outputs, suitable for low- to medium-power applications.

E36300 Series: Higher-power models with enhanced programmability and accuracy.

Key Features: High-precision voltage and current control, low noise, excellent line/load regulation, remote programmability via GPIB, USB, or LXI-core, and advanced protection features such as overvoltage and overcurrent limits. Ideal for battery testing, semiconductor characterization, and automated production lines.

ActionPower ATE

ActionPower Electric Co., Ltd. is a Chinese manufacturer specializing in high-performance programmable power supplies and automated test equipment (ATE) for power electronics, renewable energy systems, and industrial applications. Their ATE solutions integrate programmable DC/AC sources, electronic loads, and grid/battery simulation into a unified test platform, enabling engineers to perform comprehensive validation, stress testing, and functional evaluation of devices under real-world operating conditions.

ActionPower’s ATE systems are designed with high precision, fast dynamic response, and full programmability, supporting automated test sequences, data logging, and compliance verification. Their modular and scalable architecture allows for flexible power configurations, from single-channel bench-top setups to multi-megawatt systems, making them suitable for testing batteries, EV chargers, power converters, and renewable energy inverters. With advanced safety protections and integration capabilities, ActionPower ATE provides engineers with a reliable, repeatable, and efficient platform for R&D, production, and quality assurance in modern power electronics testing.

Tektronix

Tektronix is renowned for high-quality testing and measurement equipment. Their programmable power supplies are designed to meet demanding engineering applications requiring repeatable accuracy and ease of use. Tektronix focuses on providing intuitive interfaces and remote programmability, allowing engineers to automate complex testing scenarios efficiently.

Product Range and Features:

PWS4000 Series: High-precision DC power supplies with flexible outputs for lab and production testing.

PWS2000 Series: Compact models optimized for cost-effective bench-top testing with strong accuracy and regulation.

Key Features: Voltage outputs up to 800V, currents up to 100A, power ratings up to 1080W, advanced programming via USB or LAN, adjustable overvoltage protection, and multi-channel synchronization for complex test setups. They are suitable for circuit testing, component validation, and production environments.

AMETEK Programmable Power

AMETEK Programmable Power specializes in both AC and DC programmable power solutions, offering highly reliable, high-performance instruments for industrial, automotive, aerospace, and energy testing applications. They focus on modularity and scalability, enabling integration into large automated test systems.

Product Range and Features:

Sorensen Series: High-precision DC programmable power supplies with modular configurations.

XG Series: Programmable AC and DC power systems designed for complex and high-power applications.

Key Features: Output power ranging from 75W to 480kW, voltages up to 800V, currents up to 1000A, advanced automation capabilities, modular design for easy expansion, and compliance with industry safety and performance standards. These supplies are suitable for automotive component testing, aerospace electronics, and industrial power simulations.

Chroma ATE Inc.

Chroma Systems Solutions is a leading supplier of high-power and modular programmable DC power supplies for a wide range of industries, including automotive, renewable energy, aerospace, and medical electronics. Their focus is on combining high efficiency, safety, and advanced programmability to meet rigorous industrial testing requirements.

Product Range and Features:

62000P Series: Programmable DC power supplies with single-channel outputs suitable for mid- to high-power applications.

62000E Series: High-precision, high-power models for battery emulation and power electronics testing.

Key Features: Voltage ratings up to 1200V, currents up to 22.5A, output power from 1.7kW to 5kW, 100 user-programmable sequences with precise timing (5ms–15000s), adjustable overvoltage and overcurrent protection, and robust digital communication interfaces. Ideal for DC/DC converter testing, battery charging/discharging emulation, and avionics testing.

Wrap-Up

In conclusion, the leading programmable power supply manufacturers provide engineers with precise, reliable, and highly programmable power sources essential for modern R&D and testing applications. Their products support automated testing, sequence programming, and safe simulation of real-world operating conditions across industries such as automotive, renewable energy, aerospace, electronics, and medical devices.

With features like high accuracy, fast dynamic response, modular scalability, and robust protection, these power supplies enable engineers to validate components, optimize system performance, and ensure compliance with international standards efficiently. By leveraging these advanced instruments, R&D teams can accelerate innovation while maintaining repeatable, high-quality testing results.