The future of construction and industrial design is being shaped by advancements in fabrication. As projects become more complex, the demand for precision, efficiency, and sustainability continues to grow. Advanced fabrication techniques are redefining how modern structures are built. These innovations are engineering tomorrow’s world, one component at a time.

Digital Design and Precision Manufacturing

Modern fabrication begins long before steel is cut or welded. The process starts in digital environments where engineers and designers use computer-aided design (CAD) and building information modeling (BIM) to visualize and test every aspect of a structure before fabrication begins. These tools minimize human error and ensure that each part fits seamlessly during installation.

Advanced fabrication facilities also use computer numerical control (CNC) machines and laser cutters to translate digital blueprints into physical components with sub-millimeter accuracy. This integration of digital design and automation results in stronger, more consistent, and highly efficient builds that meet the increasingly tight tolerances of modern engineering projects.

Innovative Materials and Methods

Steel remains the backbone of industrial and commercial fabrication, but material technology continues to evolve. High-strength alloys, lightweight composites, and corrosion-resistant metals are becoming more common in advanced fabrication. These materials not only improve performance but also extend the lifespan of structures in harsh environments such as marine, oil and gas, and high-altitude applications.

Additionally, new methods such as modular fabrication and prefabrication are transforming how large-scale projects are executed. By fabricating major components in controlled environments off-site, teams can ensure quality, and shorten on-site construction timelines, resulting in safer and more sustainable project delivery.

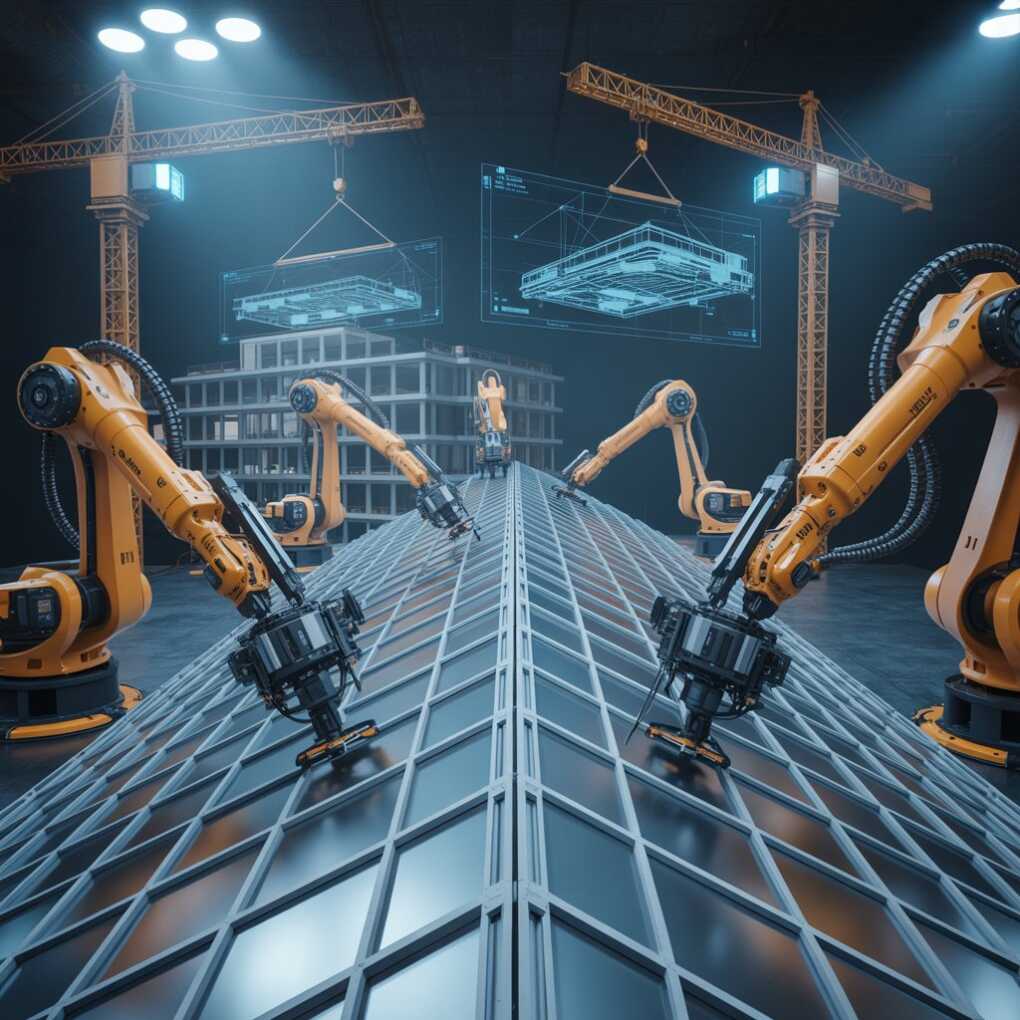

Automation and Smart Fabrication Technologies

Automation plays a central role in the next generation of fabrication. Robotic arms, AI-driven process monitoring, and digital twin technology are being used to simulate, track, and optimize fabrication processes in real time. These systems not only increase productivity but also detect and correct errors before they affect the final product.

Manufacturing (3D printing) is emerging as a complementary technology, particularly for producing custom parts, prototypes, and intricate geometries that would be difficult or expensive to achieve through traditional methods. As this technology matures, it is expected to revolutionize both small-scale and industrial fabrication applications.

Sustainability and Efficiency

As global industries push toward greener solutions, advanced fabrication methods are helping to reduce the environmental impact of construction and manufacturing. Efficient material usage, recycling of scrap metal, and energy-optimized production processes contribute to more sustainable outcomes. Many fabrication shops are also adopting smart energy management systems to reduce emissions and operational costs while maintaining productivity.

Shaping the Future of Engineering

Advanced fabrication represents the intersection of innovation, precision, and sustainability. By embracing cutting-edge tools, materials, and automation, today’s engineers are building stronger, smarter, and more efficient structures for the next generation. The future of fabrication isn’t just about what we build, it’s about how we build it.