Have you ever walked into a building and immediately felt something was just off—even though everything looked “fine”? Maybe the lines didn’t line up. Maybe the walls felt thin. Or maybe the space just lacked…intention. In this blog, we will share how design and craftsmanship are the real drivers of construction quality, far beyond blueprints and budgets.

Design That Holds Up Beyond the Render

For all the talk of innovation and technology in construction—automated framing, AI-enhanced modeling, smart sensors—it’s still design that sets the tone. Not the design on paper, but the kind that’s lived in. Design that thinks about how doors swing, where light lands in the late afternoon, or how a home expands with a family over decades. That kind of design isn’t flashy. It’s invisible, practical, deeply considered.

Modern construction is seeing a shift, not just in form but in purpose. More people are asking for function before flourish. Offices are being rethought into flexible, post-pandemic hybrids. Homes are being shaped by remote work, aging parents, and multi-use rooms. In all of it, strong design acts as the framework for every decision that follows—from materials to labor to how future-proof the structure ends up being.

When design falls short, everything downstream suffers. Suddenly you need change orders. Suddenly a door hits a cabinet. Suddenly the HVAC vents are in the worst possible place. Good design doesn’t guarantee perfection, but it minimizes conflict. It sets the bar.

Craftsmanship You Can Feel

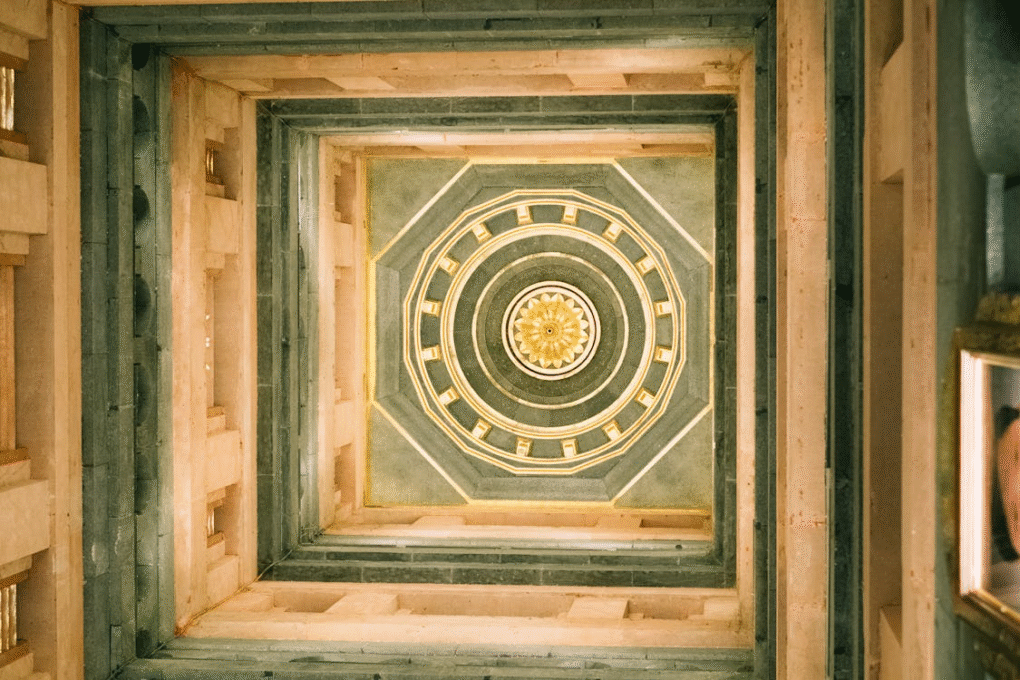

Design gets things started, but craftsmanship is where the structure becomes something you can trust. Not just visually, but physically. You know it when you feel it. The cabinet that glides like it’s floating. The stone that fits flush, no gaps. The drywall seam you can’t even find. In an age when speed is everything and prefab is gaining traction, craftsmanship has become both rarer and more valuable.

Construction quality has become harder for clients to measure because marketing often masks shortcuts. But when you focus on hands-on work, especially in detail-intensive stone projects, there’s nowhere to hide. Every cut, every polish, every placement tells you whether the crew knew what they were doing. And the difference isn’t just aesthetic—it’s structural. Precision means fewer cracks, fewer future repairs, better weather resistance, and longer-lasting beauty.

Craftsmanship also signals accountability. When a mason spends extra time leveling joints or adjusting edges until they match the blueprint exactly, they’re not just doing a job—they’re signing it, in a way. Those who’ve worked on high-end projects understand this mindset well. It’s not about luxury. It’s about performance. To know more, look at how experienced teams approach layout, spacing, and hand-finishing when they tackle complex installs—because once the stone is set, it’s going to define the space for decades, not months.

That’s what makes craftsmanship non-negotiable in any serious construction effort. It’s slow, it’s methodical, and it rarely shows up in line items labeled “value engineering.”

Cheap Doesn’t Stay Cheap

Cost-cutting has always been part of construction. But lately, it’s taken on a new urgency. Material prices soared after COVID supply chain meltdowns, labor shortages made schedules tighter, and now interest rates are punishing delays more than ever. So yes, cutting corners has gotten more tempting—but it’s also more dangerous.

The problem with shaving costs through design or labor shortcuts is that those decisions age poorly. Bad framing causes warping. Low-cost adhesives don’t survive seasonal changes. Cheap finishes fade, chip, or peel far faster than expected. And sure, it may not show up in the inspection, but it will show up in year three, when that wall has to be re-done.

This matters even more for clients investing in long-term properties—multifamily housing, commercial buildings, institutional facilities. These aren’t flippers trying to impress with backsplash patterns. These are stakeholders who don’t want to double their repair budgets because someone swapped spec’d hardware for a knockoff brand.

When Trends Compete with Longevity

Aesthetics move faster than durability. One year, it’s open shelving. The next, everyone’s resurfacing concrete. But trends don’t care about maintenance or what that finish will look like in five years after being scuffed, faded, or waterlogged.

Designers are now under pressure to create spaces that photograph well, appeal to buyers, and feel relevant to the current mood—while builders are trying to explain that matte black hardware gets destroyed in coastal environments, or that those slim tiles are a nightmare for uneven surfaces. Somewhere in between lies the balance of modern beauty and long-term buildability.

Clients need to hear both voices. The designer who knows color theory and sightlines. The contractor who’s seen what happens when someone ignores flashing. Neither one is more important than the other. But when they don’t speak early and often, you get projects that look great until they don’t. Then they cost a fortune to fix.

The Real Test Comes After the Ribbon Cutting

The best measure of construction quality doesn’t show up at the grand opening. It shows up after the first freeze. After the first leak. After the first inspection by someone with no stake in the project’s success.

A building that was designed with care and built with attention to detail will settle smoothly. Doors won’t stick. Foundations won’t crack. Maintenance won’t become a second full-time job. It’ll feel solid, even if no one can explain why.

That’s the quiet value of good design and great craftsmanship. It lets the building speak for itself, year after year, without excuses or surprises. And in an industry where so many things can go wrong, that kind of lasting quality is rare enough to be worth everything.